Kab rov tav Machining Center HMC-63W

Kab rov tav milling tshuab Nws tuaj yeem paub txog qhov drilling, milling, tho txawv, nthuav dav, reaming, tapping thiab lwm yam nyuaj nyob rau hauv ib qho clamping rau qhov nyuaj xws li ntau yam discs, phaj, plhaub, cams, thiab pwm. Ob kab thiab ib qho nyuaj qauv, haum rau ib leeg thiab loj ntau lawm ntawm ntau yam complex qhov chaw nyob rau hauv ntau yam industries.

Khoom siv

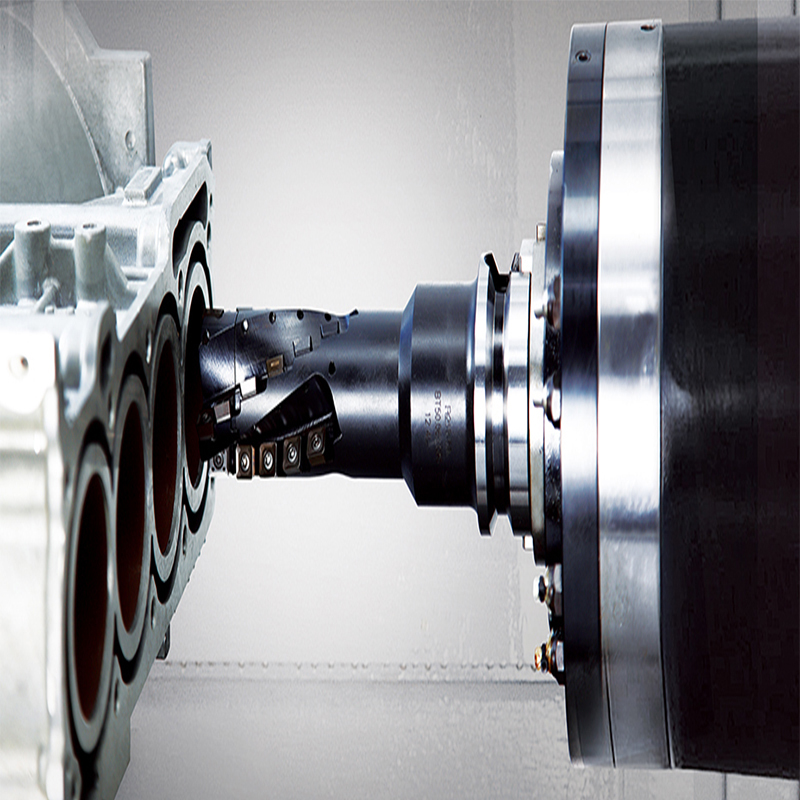

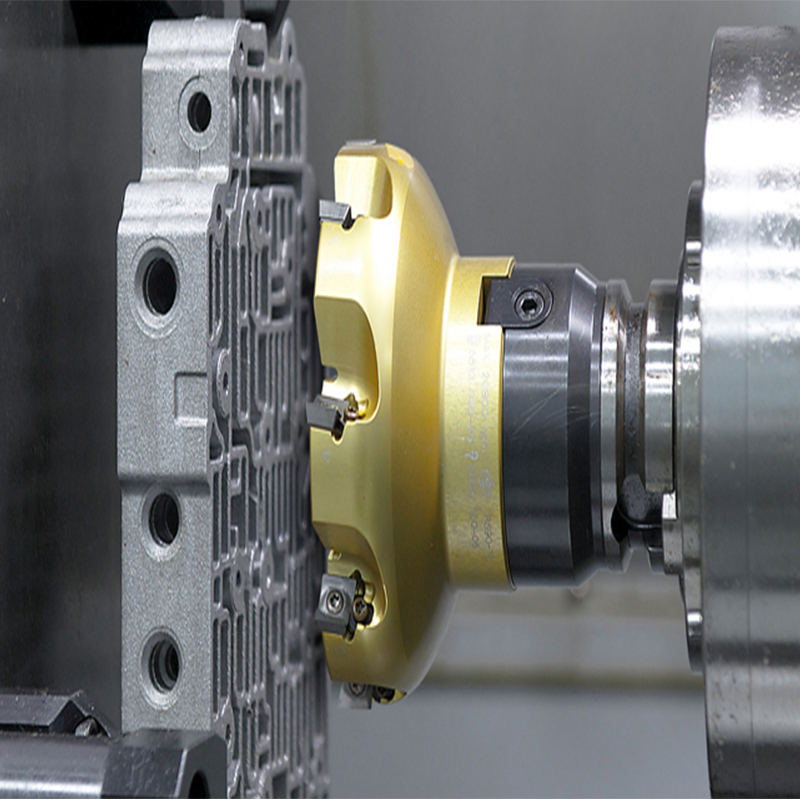

Kab rov tav machining chaw, dav siv hauv tsheb, aerospace, dav siv tshuab thiab lwm yam lag luam

Kab rov tav machining center. Feem ntau tsim nyog rau kev ua cov hlab ntsha loj thiab qhov nyuaj precision

Kab rov tav machining chaw, haum rau ntau qhov chaw ua haujlwm thiab ntau txheej txheem ntawm cov khoom

Kab rov tav machining chaw yog dav siv nyob rau hauv complex qhov chaw. Nto thiab qhov ua tiav.

Kab rov tav machining chaw yog dav siv nyob rau hauv complex qhov chaw. Nto thiab qhov ua tiav.

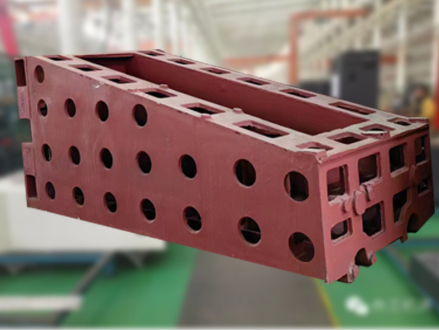

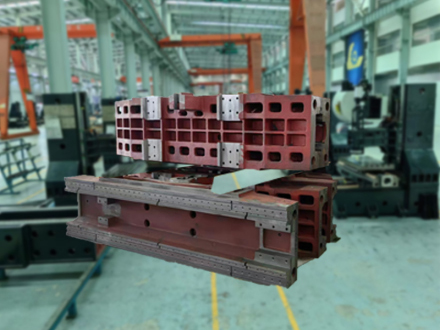

Cov txheej txheem casting khoom

CNC Kab rov tav machining chaw, lub casting txais Meehanite casting txheej txheem, thiab daim ntawv lo yog TH300.

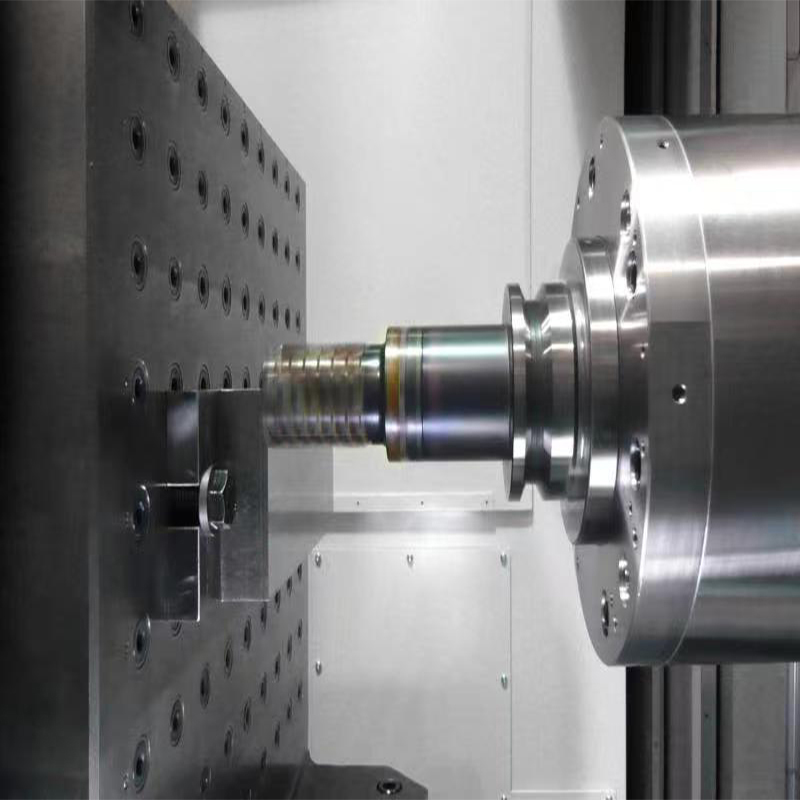

Kab rov tav milling tshuab, rooj hla swb thiab hauv paus, kom tau raws li kev txiav hnyav thiab txav ceev

Kab rov tav milling tshuab, sab hauv ntawm lub casting txais ob-walled daim phiaj-zoo li tus tav qauv.

Kab rov tav milling tshuab, lub txaj thiab txhua kab tsis ua haujlwm, txhim kho qhov tseeb ntawm qhov chaw machining.

Kab rov tav machining chaw, optimized tsim rau tsib loj castings, tsim nyog layout

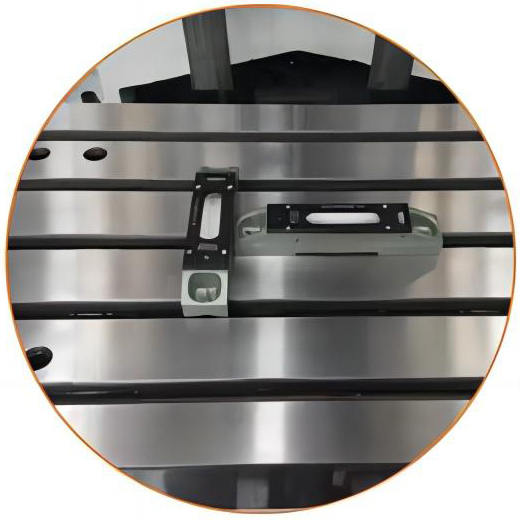

Boutique Parts

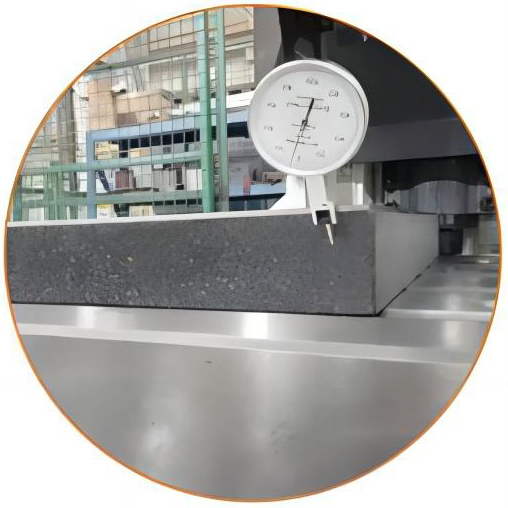

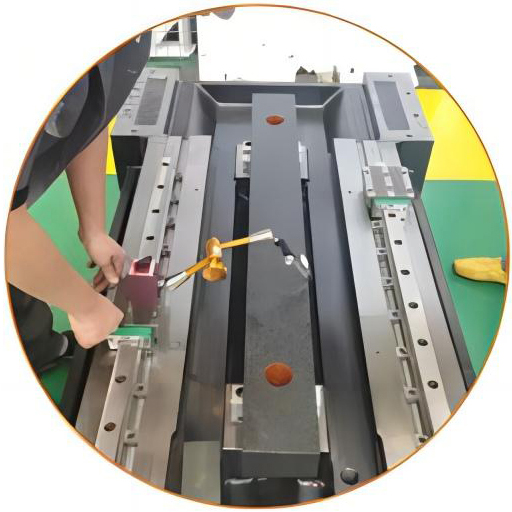

Precision sib dhos soj ntsuam txheej txheem

Workbench Qhov Ntsuas Qhov Ntsuas

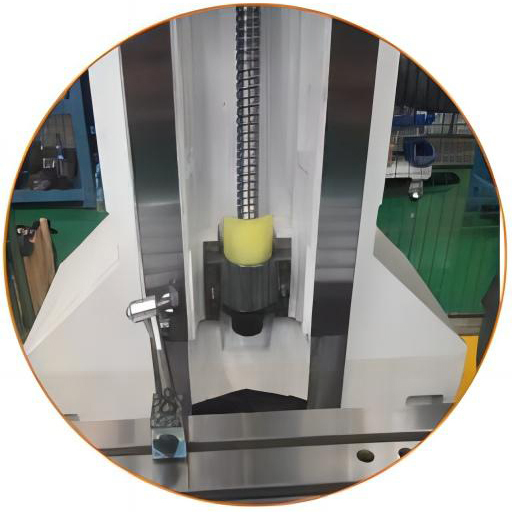

Opto-Mechanical Component Inspection

Verticality Detection

Kev Tshawb Nrhiav Parallelism

Txiv Ntseej Rooj Qhov Ntsuas Qhov Ntsuas

Angle Deviation Detection

Configure hom CNC system

TAJANE Kab rov tav machining chaw tshuab cuab yeej, raws li cov neeg siv khoom xav tau, muab ntau hom CNC tshuab kom tau raws li cov neeg siv khoom xav tau sib txawv rau ntsug machining chaw, FANUC, SIEMENS, MITSUBISH, SYNTEC.

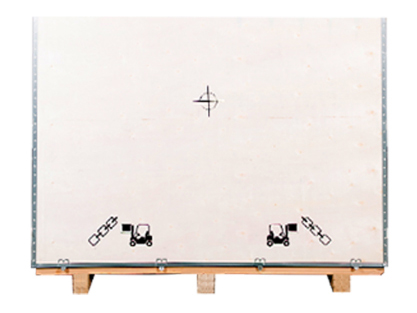

Tag nrho cov ntim ntim, escort rau kev thauj mus los

Cov khoom ntim ntoo puv nkaus

Kab rov tav Machining Center HMC-63W, tag nrho ntim pob, escort rau kev thauj mus los

Nqus ntim rau hauv lub thawv

Kab rov tav Machining Center HMC-63W, nrog noo noo-pov thawj lub tshuab nqus tsev ntim hauv lub thawv, haum rau kev thauj mus los ntev

Ntshiab cim

Kab rov tav Machining Center HMC-63W, nrog cov cim meej hauv lub thawv ntim khoom, thauj khoom thiab tshem tawm cov cim, qauv hnyav thiab qhov loj me, thiab kev lees paub siab

Khoom ntoo hauv qab bracket

Kab rov tav Machining Center HMC-63W, hauv qab ntawm lub thawv ntim khoom yog ua los ntawm cov khoom ntoo, uas yog ib qho nyuaj thiab tsis plam, thiab fastens rau xauv cov khoom.

| Specifications | HMC-63 W | |||

| Mus ncig | X-axis, Y-axis, Z-axis | X: 1050, Y: 850, Z: 950mm | ||

| Spindle Nose Rau Pallet | 150-1100 hli | |||

| Spindle Center Rau Pallet Nto | 90-940 hli | |||

| Rooj | Rooj Loj | 630 x 630 mm | ||

| Workbench Number | 1 (OP:2) | |||

| Workbench Surface Configuration | M16-125 hli | |||

| Lub Workbench Maximum Load | 1200 kg | |||

| Qhov Chaw Me Me ntawm Chaw | 1 ° (OP: 0.001 °) | |||

| Controller thiab Motor | 0 IMF - IB | 0IMF-a | 0 IMF - IB | |

| Spindle Tsav | 15/18.5 kW (143.3Nm) | 22/26 kW (140 Nm) | 15/18.5 kW (143.3Nm) | |

| X Axis Servo Tsav | 3 kW (36 Nm) | 7 kW (30 Nm) | 3 kW (36 Nm) | |

| Y Axis Servo Tsav | 3 kW (36 Nm) BS | 6 kW (38 Nm) BS | 3 kW (36 Nm) BS | |

| Z Axis Servo Tsav | 3 kW (36 Nm) | 7 kW (30 Nm) | 3 kW (36 Nm) | |

| B Axis Servo Tsav | 2.5 kW (20 Nm) | 3 kW (12 Nm) | 2.5 kW (20 Nm) | |

| Pub tus nqi | 0 IMF - IB | 0IMF-a | 0 IMF - IB | |

| X. Z Axis Rapid Feed Rate | 24m / min | 24m / min | 24m / min | |

| Y Axis Rapid Feed Rate | 24m / min | 24m / min | 24m / min | |

| XY Z Max.Cutting Feed Rate | 6m / min | 6m / min | 6m / min | |

| ATC | Arm Hom (Tswj rau Cuab Yeej) | 30T (4.5 sec) | ||

| Tool Shank | BT-50 | |||

| Max. Tool Diameter * Length (nyob ib sab) | φ200 * 350mm (φ105 * 350mm) | |||

| Max. Tool Qhov hnyav | 15kg ua | |||

| Tshuab raug | Positioning Accuracy (JIS) | ± 0.005mm / 300mm | ||

| Repeat Poitioning Accuracy (JIS) | ± 0.003 hli | |||

| Lwm tus | Kwv yees qhov hnyav | A: 15500kg / B: 17000kg | ||

| Kev ntsuas qhov chaw hauv pem teb | A: 6000 * 4600 * 3800mm B: 6500 * 4600 * 3800mm | |||

Standard Accessories

● Spindle thiab servo motor load zaub

● Spindle thiab servo overload tiv thaiv

● Rigid tapping

● Cov npog npog npog tag nrho

● Electronic handwheel

● Teeb pom kev zoo

● Muab ob npaug rau kauv nti conveyor

● Tsis siv neeg lubrication system

● Lub thawv hluav taws xob ntsuas kub

● Spindle cuab tam txias system

● RS232 interface

●Airsoft phom

● Spindle taper ntxuav

●Toolbox

Xaiv cov khoom siv

● Peb-axis grating tus pas ntsuas ntsuas

● Workpiece ntsuas qhov system

● Cov cuab yeej ntsuas qhov system

● Spindle nrog cua txias

● CNC rotary rooj

●Chain nti conveyor

●Tool length setter thiab edge finder

● Dej Separator

● Spindle dej txias ntaus ntawv

● Internet muaj nuj nqi