CNC machining chaw: lub hauv paus ntawm advanced manufacturing technology

I. Kev Taw Qhia

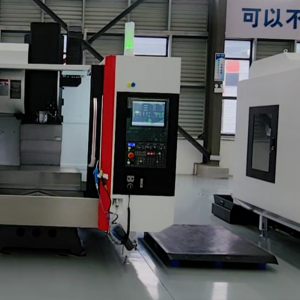

Hauv kev lag luam niaj hnub tsim,CNC machining chaw, raws li lub tshuab CNC tseem ceeb, ua lub luag haujlwm tseem ceeb. Nws koom ua ke nrog cov thev naus laus zis thiab kev ua haujlwm kom ua tiav cov haujlwm ua haujlwm tau zoo thiab raug thiab muab cov khoom zoo thiab cov khoom lag luam rau ntau yam kev lag luam. Kab lus no yuav sib tham tob txog cov yam ntxwv, ua cov hauv paus ntsiab lus, qhov zoo thiab qhov tsis zoo ntawmCNC machining chaw, thiab txheeb xyuas lawv daim ntawv thov thiab kev txhim kho yav tom ntej hauv kev tsim khoom lag luam.

II. Cov yam ntxwv ntawm CNC Machining Center

CNC machining chaw yog tsim los ntawm lub hauv paus ntawmCNC milling tshuab, tab sis nws muaj cov yam ntxwv tshwj xeeb uas paub qhov txawv ntawm CNC milling tshuab. Ib qho tseem ceeb tshaj plaws yog nws lub tsev qiv ntawv riam thiab lub peev xwm los hloov cov riam. Los ntawm cov cuab yeej hloov pauv tsis siv neeg no, lub chaw machining tuaj yeem hloov ntau yam cuab yeej sib txawv hauv ib qho clamping, kom ua tiav ntau yam kev ua haujlwm nyuaj. Qhov no feature zoo heev txhim kho cov kev ua tau zoo thiab yoog raws, txo tus naj npawb ntawm clamping ntawm workpieces, thiab txo qhov ua tau ntawm machining yuam kev.

Tsis tas li ntawd, CNC machining chaw yog feem ntau nruab nrog high-precision tswj tshuab thiab kev tsav tsheb siab heev, uas tuaj yeem ua kom qhov tseeb thiab ruaj khov ntawm machining. Nws tuaj yeem ua cov khoom ua haujlwm ntawm ntau cov duab thiab qhov ntau thiab tsawg, txawm tias nws yooj yim geometry lossis cov chaw nyuaj, uas tuaj yeem daws tau yooj yim. Nyob rau tib lub sijhawm, lub chaw machining tseem muaj peev xwm txiav tau zoo thiab kev ua haujlwm siab ceev, uas tuaj yeem ua tau raws li cov kev xav tau ntawm kev lag luam sib txawv rau kev ua haujlwm zoo thiab kev ua haujlwm zoo.

III. Cov ntsiab cai rau kev txiav txim siab ntawm cov txheej txheem ua

Nyob rau hauv tus txheej txheem ntawm CNC machining chaw, nws yog ib qho tseem ceeb heev kom txiav txim siab txoj kev ua. Cov hauv qab no yog cov hauv paus ntsiab lus uas feem ntau ua raws:

1. Xyuas kom meej qhov tseeb thiab nto roughness ntawm lub workpiece: Tus tsim ntawm machining txoj kev yuav tsum xub xav txog yuav ua li cas los xyuas kom meej qhov tseeb thiab nto roughness yuav tsum tau ntawm cov txheej txheem workpiece. Qhov no yuav tsum muaj kev txiav txim siab zoo ntawm yam xws li kev xaiv cov cuab yeej, txiav qhov kev teeb tsa thiab kev ua tiav machining. Los ntawm kev npaj tsim nyog, kev ua yuam kev tuaj yeem raug txo qis thiab cov khoom ua haujlwm zoo tuaj yeem txhim kho.

2. Shorten txoj kev ua: Txhawm rau txhim kho kev ua tau zoo, txoj kev ua haujlwm yuav tsum tau luv kom ntau li ntau tau thiab lub sijhawm mus ncig yuav tsum tau txo. Qhov no tuaj yeem ua tiav los ntawm kev txhim kho cov cuab yeej txoj hauv kev thiab tsim nyog npaj cov txheej txheem ua tiav. Nyob rau tib lub sijhawm, zam kev tsis tsim nyog rov ua dua thiab txoj hauv kev ncig kom txuag tau sijhawm thiab lub zog.

3. Kev suav lej yooj yim: Kev txiav txim siab ntawm txoj kev ua haujlwm yuav tsum ua kom yooj yim rau kev ua haujlwm ntawm kev suav lej ntau npaum li qhov ua tau rau kev ua haujlwm thiab kev ua haujlwm. Qhov no tuaj yeem ua tiav los ntawm kev xaiv qhov tsim nyog kev sib koom tes thiab siv cov txheej txheem cuab yeej trajectory. Kev ua kom yooj yim ntawm kev ua haujlwm tuaj yeem tsis tsuas yog txhim kho kev ua haujlwm ntawm kev ua haujlwm, tab sis kuj txo qhov ua tau ntawm kev ua yuam kev.

4. Kev siv cov txheej txheem subroutines: Rau qee qhov kev siv rov qab siv dua, cov txheej txheem subroutines yuav tsum tau siv rau kev ua haujlwm. Qhov no tuaj yeem txo qhov ntev ntawm qhov kev zov me nyuam thiab txhim kho qhov ua tau zoo thiab kev nyeem tau ntawm cov programming. Nyob rau tib lub sijhawm, cov txheej txheem subroutine kuj tuaj yeem hloov kho tau yooj yim thiab khaws cia los txhim kho qhov yooj yim thiab rov siv tau ntawm qhov program.

IV. Qhov zoo ntawmCNC Machining Center

CNC machining chawmuaj ntau yam zoo, uas ua rau nws siv dav hauv kev lag luam niaj hnub no:

1. Txo tus naj npawb ntawm cov cuab yeej: Vim tias lub chaw machining tuaj yeem ua tiav ntau yam kev ua haujlwm los ntawm kev hloov cov cuab yeej tsis siv neeg, nws tsis xav tau ntau cov cuab yeej nyuaj thaum ua cov khoom nrog cov duab nyuaj. Tsuas yog los ntawm kev hloov kho cov txheej txheem ua haujlwm, kev ua haujlwm ntawm qhov sib txawv ntawm cov duab thiab qhov ntau thiab tsawg tuaj yeem ua tiav, uas ua rau kom muaj nuj nqis thiab tus nqi ntawm cov cuab yeej zoo heev. Qhov no muaj txiaj ntsig zoo rau kev txhim kho thiab hloov kho cov khoom tshiab, thiab tuaj yeem teb sai sai rau kev lag luam xav tau.

2. Kev ua haujlwm ruaj khov: Lub chaw machining yog nruab nrog cov kev tswj xyuas siab thiab kev tsav tsheb siab heev, uas tuaj yeem ua kom ruaj khov ntawm kev ua haujlwm. Nws muaj kev ua haujlwm siab thiab rov ua dua, uas tuaj yeem ua tau raws li cov kev xav tau ntawm high-precision industries xws li aircraft. Tsis tas li ntawd, cov txheej txheem ua haujlwm ntawm qhov chaw ua haujlwm yog qhov ruaj khov thiab tsis tshua muaj kev cuam tshuam los ntawm tib neeg cov yam ntxwv, uas yog qhov tsim nyog los xyuas kom meej qhov sib xws ntawm cov khoom zoo.

3. High efficiency efficiency: nyob rau hauv cov ntaub ntawv ntawm ntau-ntau thiab me me-ntim ntau lawm, lubCNC machining chawtuaj yeem muab kev ua si tag nrho rau nws cov txiaj ntsig zoo. Los ntawm kev txo lub sijhawm ntawm kev npaj ntau lawm, kev hloov kho tshuab thiab kev tshuaj xyuas cov txheej txheem, thiab siv cov txiav txiav zoo tshaj plaws los txo cov sij hawm txiav, qhov chaw machining tuaj yeem txhim kho kev ua haujlwm zoo. Nyob rau tib lub sijhawm, nws cov peev txheej ua tau yooj yim kuj tuaj yeem ua tau raws li tus kheej xav tau ntawm cov neeg siv khoom sib txawv thiab txhim kho kev lag luam kev sib tw ntawm kev lag luam.

4. Qhov chaw nyuaj uas tuaj yeem ua tiav:CNC machining chawtuaj yeem ua cov txheej txheem nyuaj uas nyuaj rau txheej txheem los ntawm cov txheej txheem ib txwm, xws li cov npoo nkhaus, qhov tshwj xeeb zoo li tus, thiab lwm yam. Txawm tias qee qhov kev ua haujlwm tsis zoo, nws tuaj yeem ua tiav los ntawm kev tswj cov lej siab heev. Qhov no muab qhov dav dav tsim qhov chaw thiab kev tsim khoom muaj peev xwm rau kev tsim khoom lag luam, thiab pab txhawb cov khoom lag luam innovation thiab kho dua tshiab.

V. Qhov tsis zoo ntawm CNC Machining Center

Txawm hais tias CNC machining chaw muaj ntau qhov zoo, kuj tseem muaj qee qhov tsis txaus uas yuav tsum tau them nyiaj rau:

1. Tus nqi ntawm cov cuab yeej siv tshuab yog kim: cov khoom siv tus nqi ntawmCNC machining chawyog qhov tseem ceeb, uas tej zaum yuav yog ib qho peev txheej loj rau qee lub lag luam me thiab nruab nrab. Tsis tas li ntawd, nws cov nqi txij nkawm thiab kev saib xyuas kuj tseem siab, uas yuav tsum muaj cov kws tshaj lij kev lag luam los ua haujlwm thiab tswj xyuas.

2. Yuav tsum muaj kev saib xyuas cov neeg ua haujlwm kom muaj qib siab: Txij li thaum CNC machining chaw yog ib qho khoom siv high-techCNC tshuab cuab yeej, nws kho thiab tu yuav tsum muaj kev txawj ntse thiab kev txawj ntse. Cov neeg ua haujlwm saib xyuas yuav tsum paub txog cov qauv, lub hauv paus ntsiab lus thiab kev tswj hwm ntawm cov cuab yeej siv tshuab, thiab tuaj yeem txiav txim siab sai thiab raug thiab daws qhov yuam kev. Rau cov lag luam, nws yog ib qho tsim nyog los cob qhia lossis nrhiav cov neeg ua haujlwm zoo, uas ua rau cov nqi ua haujlwm ntawm lub tuam txhab nce ntxiv.

VI. Daim ntawv thov ntawm CNC Machining Center

CNC machining chaw yog dav siv nyob rau hauv ntau yam lag luam. Cov hauv qab no yog qee qhov kev thov ua haujlwm:

1. Aerospace teb: Nyob rau hauv aerospace teb, qhov tseeb thiab zoo ntawm cov khoom yog siab heev. CovCNC machining chawtuaj yeem ua tiav ntau yam ntawm cov duab nyuaj, xws li dav hlau cav hniav, qhov chaw tsim khoom siv dav hlau, thiab lwm yam, kom ua tau raws li qhov xav tau siab hauv thaj chaw aerospace.

2. Automotive manufacturing kev lag luam: Automotive manufacturing kev lag luam yog ib qho tseem ceeb daim ntawv thov teb ntawm CNC machining chaw. CNC machining chaw tuaj yeem siv los ua cov khoom tseem ceeb xws li tsheb cav lub tog raj kheej thaiv, lub tog raj kheej lub taub hau thiab crankshaft, nrog rau cov khoom loj xws li lub tsheb lub cev thiab chassis. Nws muaj peev xwm ua tau zoo thiab muaj tseeb tuaj yeem txhim kho qhov zoo thiab ua haujlwm ntawm kev tsim tsheb.

3. Pwm manufacturing kev lag luam: Mould manufacturing yog lwm daim ntawv thov tseem ceeb teb ntawmCNC machining chaw. Qhov raug thiab zoo ntawm cov pwm ncaj qha cuam tshuam rau qhov zoo thiab kev ua haujlwm ntawm cov khoom. CNC machining chaw tuaj yeem ua cov txheej txheem ntau yam ntawm cov pwm, xws li kev txhaj tshuaj pwm, tuag-casting pwm, stamping pwm, thiab lwm yam., muab kev pabcuam txhim khu kev qha rau kev tsim pwm kev lag luam.

4. Kev lag luam Electronics: Hauv kev lag luam hluav taws xob,CNC machining chawtuaj yeem siv los ua ntau yam khoom siv hluav taws xob, xws li cov ntawv luam tawm, cov xov tooj ntawm tes, lub plhaub hauv computer, thiab lwm yam. Nws muaj peev xwm ua tau zoo thiab ceev ceev tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev lag luam hluav taws xob rau qhov raug thiab zoo ntawm cov khoom.

5. Kev lag luam khoom siv kho mob: Kev lag luam khoom siv kho mob kuj tseem muaj cov kev xav tau siab heev rau qhov raug thiab zoo ntawm qhov chaw. CNC machining chaw tuaj yeem ua tiav ntau yam khoom siv kho mob, xws li cov cuab yeej phais, cov cuab yeej kho mob, thiab lwm yam, muab cov txheej txheem tsim khoom tseem ceeb rau kev lag luam khoom siv kho mob.

Xya. Kev txhim kho yav tom ntej ntawmCNC Machining Center

Nrog kev nce qib ntawm kev tshawb fawb thiab thev naus laus zis thiab kev txhim kho txuas ntxiv ntawm kev tsim khoom lag luam, CNC machining chaw tseem yuav ua rau muaj kev txhim kho tshiab thiab cov teeb meem. Nov yog qee qhov kev txhim kho yav tom ntej:

1. Txawj Ntse: Lub neej yav tom ntejCNC machining chawyuav ntse dua, nrog rau kev kawm ywj pheej, kev hloov kho thiab lwm yam haujlwm. Los ntawm kev siv cov cuab yeej txawj ntse technology, lub chaw machining tuaj yeem ua kom zoo dua qhov kev ua haujlwm tsis zoo thiab cov cuab yeej siv raws li cov yam ntxwv thiab kev ua haujlwm ntawm cov khoom ua haujlwm, thiab txhim kho kev ua haujlwm zoo thiab ua haujlwm zoo.

2. Kev kub ceev: Nrog kev txhim kho tas mus li ntawm cov kev xav tau ntawm kev tsim khoom lag luam rau kev tsim cov khoom lag luam, kev loj hlob ceev ntawm CNC machining chaw yuav dhau los ua qhov sib txawv. Nyob rau hauv lub neej yav tom ntej, lub chaw machining yuav muaj ntau dua spindle ceev, ceev ceev ceev thiab ntau dua acceleration kom ua tau zoo dua machining hauj lwm.

3. Kev sib xyaw ua ke: txhawm rau ua kom tau raws li qhov xav tau ntawm kev tsim khoom lag luam rau kev ua haujlwm ntau, covCNC machining chawyuav tsim nyob rau hauv kev coj ntawm kev sib xyaw. Lub chaw machining yav tom ntej yuav koom ua ke ntau yam kev ua haujlwm, xws li tig, milling, drilling, tapping, thiab lwm yam., kom ua tiav ntau lub hom phiaj ib lub tshuab thiab txhim kho kev siv tus nqi thiab kev ua haujlwm ntawm cov khoom siv.

4. Greening: Nrog rau kev txhim kho tas mus li ntawm ib puag ncig kev paub, kev loj hlob ntsuab ntawmCNC machining chawtseem yuav dhau los ua ib qho tseem ceeb tshaj plaws rau yav tom ntej. Lub chaw ua haujlwm yav tom ntej yuav tau txais ntau lub zog-txuag thiab ib puag ncig tus phooj ywg thev naus laus zis thiab cov khoom siv los txo qis kev siv hluav taws xob thiab kev ua qias tuaj ib puag ncig.

5. Networked: Nrog kev txhim kho txuas ntxiv ntawm cov ntaub ntawv thev naus laus zis, kev tsim kho network ntawmCNC machining chawtseem yuav dhau los ua ib qho tseem ceeb tshaj plaws rau yav tom ntej. Lub chaw machining yav tom ntej yuav tuaj yeem txuas thiab cuam tshuam nrog lwm yam khoom siv thiab cov tshuab hauv lub network, paub txog kev saib xyuas tej thaj chaw deb, kev kuaj xyuas qhov tsis raug, kev pab cuam kis tau tus mob thiab lwm yam haujlwm, thiab txhim kho kev ua tau zoo thiab kev txawj ntse ntawm kev tswj cov khoom.

VIII. Xaus

Raws li ib tug advancedCNC tshuab cuab yeej, CNC machining center plays lub luag haujlwm tseem ceeb hauv kev tsim khoom niaj hnub. Nws muaj cov yam ntxwv tshwj xeeb thiab qhov zoo, tuaj yeem paub txog kev ua haujlwm zoo thiab raug, thiab muab cov khoom zoo thiab cov khoom lag luam rau ntau yam lag luam. Nrog kev nce qib ntawm kev tshawb fawb thiab thev naus laus zis thiab kev txhim kho txuas ntxiv ntawm kev tsim khoom lag luam, CNC machining chaw tseem yuav txuas ntxiv txhim kho thiab txhim kho, muab kev txhawb zog rau kev tsim kho kev lag luam. Nyob rau yav tom ntej,CNC machining chawyuav txhim kho nyob rau hauv cov kev taw qhia ntawm kev txawj ntse, kev kub ceev, compounding, ntsuab thiab kev sib txuas lus, ua kom muaj kev koom tes ntau dua rau kev hloov pauv thiab kev txhim kho thiab kev txhim kho zoo ntawm kev tsim khoom.

Millingmachine@tajane.comNov yog kuv tus email chaw nyob. Yog tias koj xav tau, koj tuaj yeem xa email rau kuv. Kuv tab tom tos koj tsab ntawv nyob rau Suav teb.