Vertical machining center VMC-1100

Lub hom phiaj

TAJANE ntsug machining chaw VMC-1100 series tshwj xeeb yog tsim los rau kev ua haujlwm nyuaj xws li cov hlau phaj, disc-shaped qhov chaw, pwm thiab cov tsev me me. Lub chaw ntsug machining tuaj yeem ua haujlwm zoo xws li milling, tho txawv, drilling, tapping thiab xov txiav, muab cov kev daws teeb meem rau cov hlau ua haujlwm hauv ntau yam.

Khoom siv

TAJANE ntsug machining chaw VMC-1100 series tuaj yeem siv los ua cov txheej txheem precision ntawm 5G cov khoom, thiab tuaj yeem ua tau raws li cov kev xav tau ntawm lub plhaub, qhov chaw pib thiab ntau yam pwm. Tsis tas li ntawd, nws tuaj yeem paub txog kev ua haujlwm siab ceev ntawm lub thawv-hom qhov chaw, txhim kho kev ua tau zoo thiab kev ua haujlwm raug.

Vertical machining center 5G precision qhov chaw ua

Vertical machining chaw rau batch ua ntawm plhaub qhov chaw

Vertical machining chaw rau nws pib qhov chaw ua

Vertical machining chaw rau lub thawv-hom qhov ua tiav

Vertical machining chaw rau pwm qhov chaw ua haujlwm

Cov txheej txheem casting khoom

Rau CNC VMC-1100 ntsug machining center series, cov castings txais yuav Meehanite casting txheej txheem nrog rau qib TH300, uas muaj lub zog siab thiab hnav tsis kam. Sab hauv ntawm cov castings ntawm VMC-1100 ntsug machining chaw yog tsim los nrog ib tug ob-phab ntsa kab sib chaws-zoo li rib qauv. Tsis tas li ntawd, lub ntuj aging kev kho mob ntawm lub txaj thiab kem ntawm VMC-1100 ntsug machining chaw zoo txhim kho qhov tseeb ntawm machining chaw. Lub worktable cross swb thiab hauv paus tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev txiav hnyav thiab txav nrawm, muab cov neeg siv nrog kev ua haujlwm zoo dua thiab ruaj khov.

Yuav ua li cas kom txo tau qhov tsis-conforming tus nqi ntawm

ntsug machining center castings rau 0.3%

CNC ntsug machining chaw, nrog ob-walled grid-zoo li tav qauv nyob rau hauv lub casting.

CNC ntsug machining chaw, lub thawv spindle txais kev tsim qauv tsim nyog thiab tsim nyog.

Vertical machining center txaj thiab kem undergo natural aging rau siab dua precision.

CNC ntsug machining chaw, rooj hla swb thiab hauv paus, kom tau raws li kev txiav hnyav thiab txav ceev

Cov khoom sib dhos txheej txheem

Nyob rau hauv VMC-1100 ntsug machining chaw, kev ruaj ntseg ntawm lub tshuab cuab yeej precision thiab rigidity yog txhim khu kev qha los ntawm cov scraping ntawm kev sib cuag ntawm cov khoom xws li lub rooj zaum bearing, kev sib cuag ntawm lub worktable txiv ntseej lub rooj zaum thiab slider, kev sib cuag nto ntawm lub spindle box thiab spindle, thiab kev sib cuag ntawm lub hauv paus thiab kem. Nyob rau tib lub sijhawm, nws tshem tawm cov kev ntxhov siab sab hauv hauv lub tshuab cuab yeej, txo kev sib txhuam, thiab ua kom lub neej ntev kev pab cuam ntawm ntsug machining chaw.

Yuav ua li cas yog lub precision ntawm ib tug ntsug machining chaw "scraped tawm"?

① Scraping thiab lapping ntawm bearing lub rooj ntawm ntsug machining chaw

② Scraping thiab lapping ntawm qhov chaw sib cuag ntawm lub rooj zaum lub rooj zaum thiab lub slider

③ Qhov chaw sib cuag ntawm lub taub hau thiab cov ntxaiv ntawm qhov chaw ntsug machining

④ Scraping thiab lapping ntawm qhov chaw sib cuag ntawm lub hauv paus thiab kab

Kev tshuaj xyuas qhov tseeb

Tag nrho cov khoom nyob rau hauv lub CNC VMC-1100 ntsug machining chaw series undergo precision tshuaj ntsuam xyuas ua ntej tawm hauv lub Hoobkas. Cov no suav nrog kev tshuaj xyuas qhov tseeb geometric, kev tshuaj xyuas qhov tseeb ntawm qhov chaw, kuaj txiav qhov tseeb, thiab kev soj ntsuam xyuas qhov tseeb ntawm laser interferometer. Txhua kauj ruam yuav tsum tau ntau yam kev ntsuas los xam qhov nruab nrab tus nqi, thiaj li yuav txo tau qhov yuam kev yuam kev, xyuas kom meej cov kev tshwm sim, thiab ua kom tiav high-speed, high-precision, thiab high-efficiency machining teebmeem.

Workbench Qhov Ntsuas Qhov Ntsuas

Opto-mechanical soj ntsuam

Verticality Detection

Kev Tshawb Nrhiav Parallelism

Nut Seat Kev soj ntsuam xyuas

Angle Deviation Detection

Tsim nta

Cov khoom tseem ceeb ntawm lub tshuab cuab yeej lub cev rau VMC-1100 series ntsug machining chaw yog ua los ntawm HT300 high-strength grey cam khwb cia hlau, nyob rau hauv kev kho cua sov, natural aging thiab precision txias ua. Nws txais yuav ib kem herringbone, nrog rau lub cev hnyav rau Z-axis. Cov kev taw qhia rails yog manually scraped, txhim kho rigidity thiab tsis txhob machining vibration.

Video ntawm ntsug machining center castings

Vertical machining center lub teeb tshuab

Vertical machining center Bearing Spindle

Vertical machining center Bearing

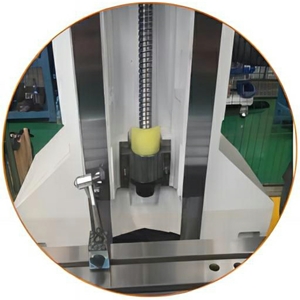

CNC ntsug machining chaw, Lead ntsia hlau

Kev ntim khoom ruaj khov

Tag nrho cov txheej txheem ntawm CNC VMC-1100 ntsug machining chaw yog ntim rau hauv cov thawv ntim ntoo, nrog cov ntaub ntawv pov thawj noo noo hauv cov rooj plaub. Lawv tsim nyog rau kev thauj mus los ntev xws li kev thauj mus los hauv av thiab hauv hiav txwv. Txhua qhov ntsug machining chaw tuaj yeem ua kom nyab xeeb thiab xa mus rau txhua qhov chaw ntawm lub ntiaj teb.

Xauv kev sib txuas, ruaj thiab tensile.

Kev xa khoom pub dawb rau cov chaw nres nkoj loj thiab cov chaw nres nkoj kev lis kev cai thoob tebchaws.

Tshem tawm cov cim

Xauv kev sib txuas

Khoom ntoo central axis

Lub tshuab nqus tsev ntim

Cov khoom siv txheem

Tus qauv kev teeb tsa ntawm tag nrho cov series ntawm VMC-850 Vertical Machining Centers yog tus yuam sij rau kev ua kom ruaj khov realization ntawm cov tub ntxhais machining zog. Nws tsim kev lees paub los ntawm peb qhov tseem ceeb: kev tiv thaiv kev nyab xeeb, kev ua haujlwm ruaj khov, thiab kev ua haujlwm yooj yim. Nws yog haum rau ua tau raws li cov kev xav tau ntawm cov pa hlau txiav cov txheej txheem thiab nteg lub hauv paus rau ntau lawm efficiency thiab machining zoo.

Cov khoom siv ntxiv

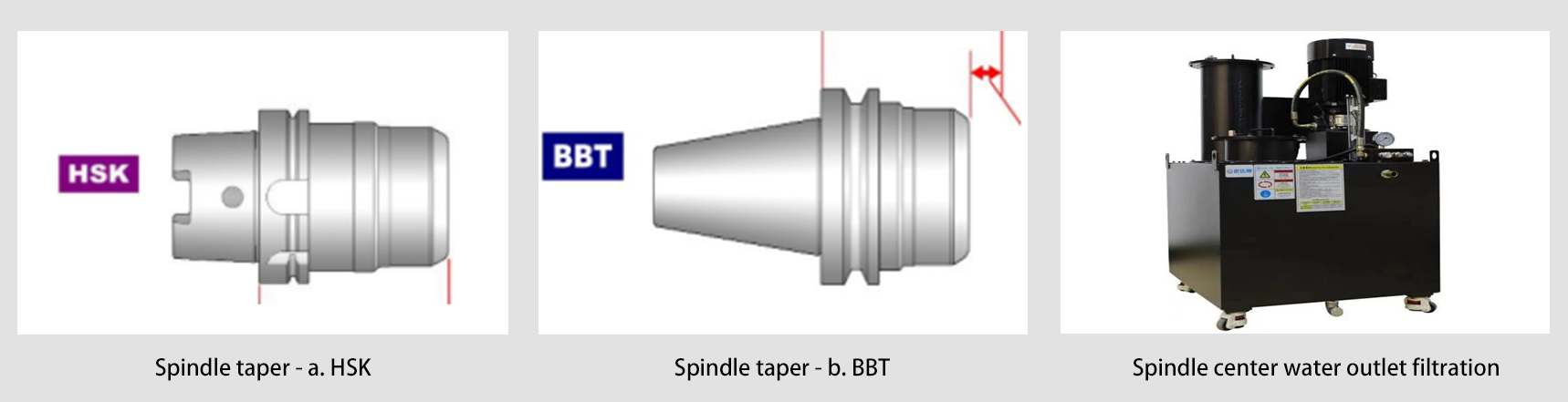

I. Rau ntau yam ntawm VMC-850 ntsug machining chaw, xaiv spindles muaj raws li cov khoom siv ntxiv:

II. Rau tag nrho cov ntau yam ntawm VMC-850 ntsug machining chaw, spindle taper hom thiab spindle chaw dej qhov hluav taws xob pom systems muaj raws li cov khoom siv ntxiv:

III. Rau tag nrho ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv cuab yeej setter yog muaj raws li cov khoom siv ntxiv:

IV. Rau tag nrho cov ntau yam ntawm VMC-850 ntsug machining chaw, xaiv linear scale thiab workpiece ntsuas OMP60 yog muaj raws li cov cuab yeej ntxiv:

V. Rau ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv cov cuab yeej magazine muaj raws li cov khoom siv ntxiv:

VI. Rau ntau yam ntawm VMC-850 ntsug machining chaw, xaiv yooj yim roj-dej separators thiab roj pos huab collectors muaj raws li cov khoom siv ntxiv:

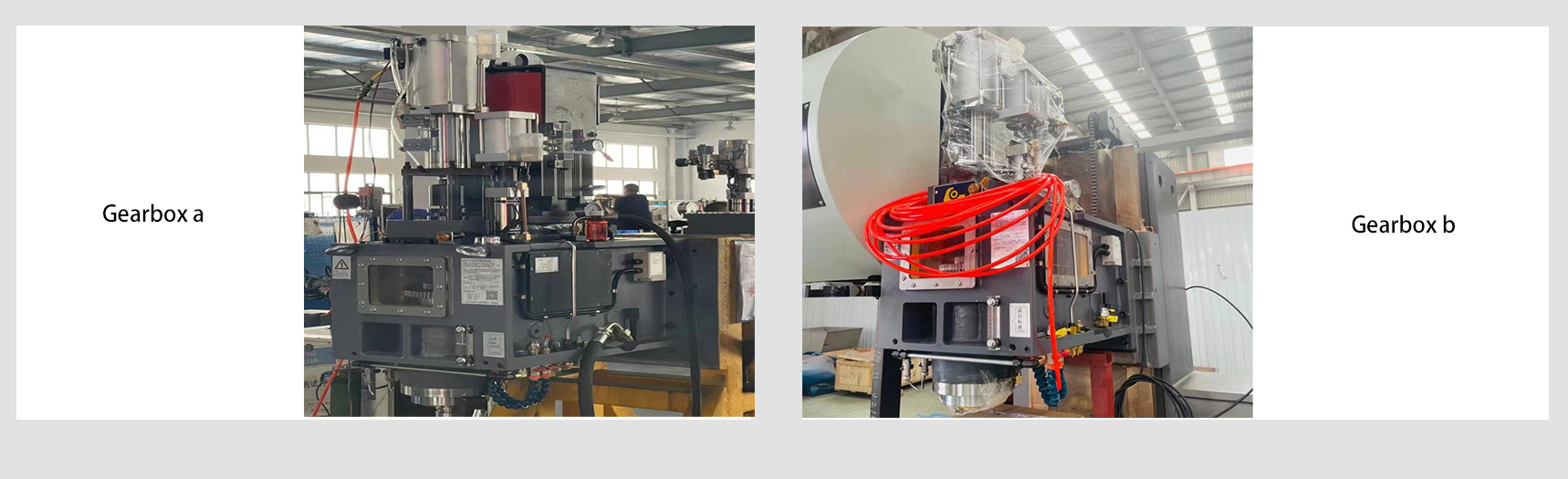

VII. Rau ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv gearbox muaj raws li cov khoom siv ntxiv:

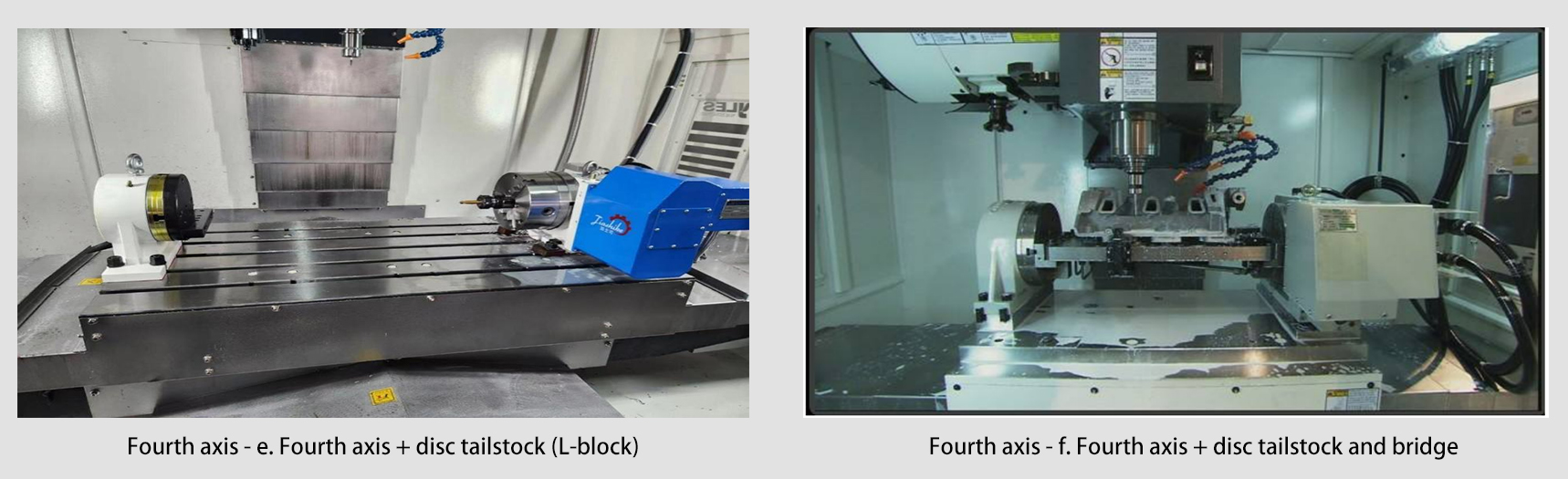

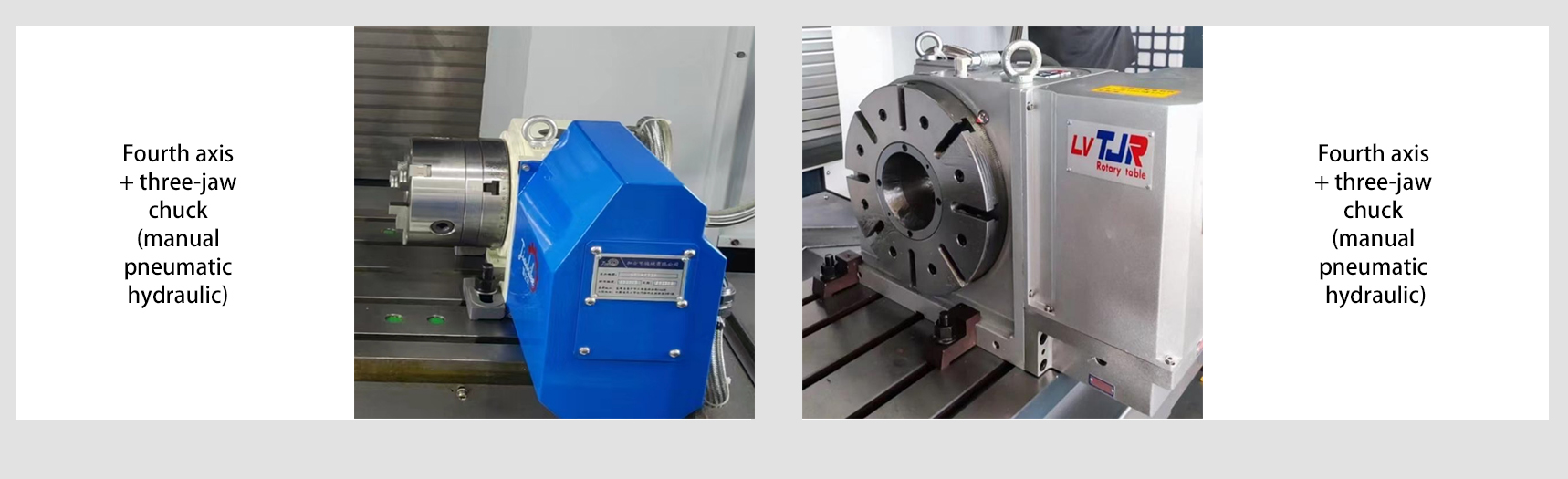

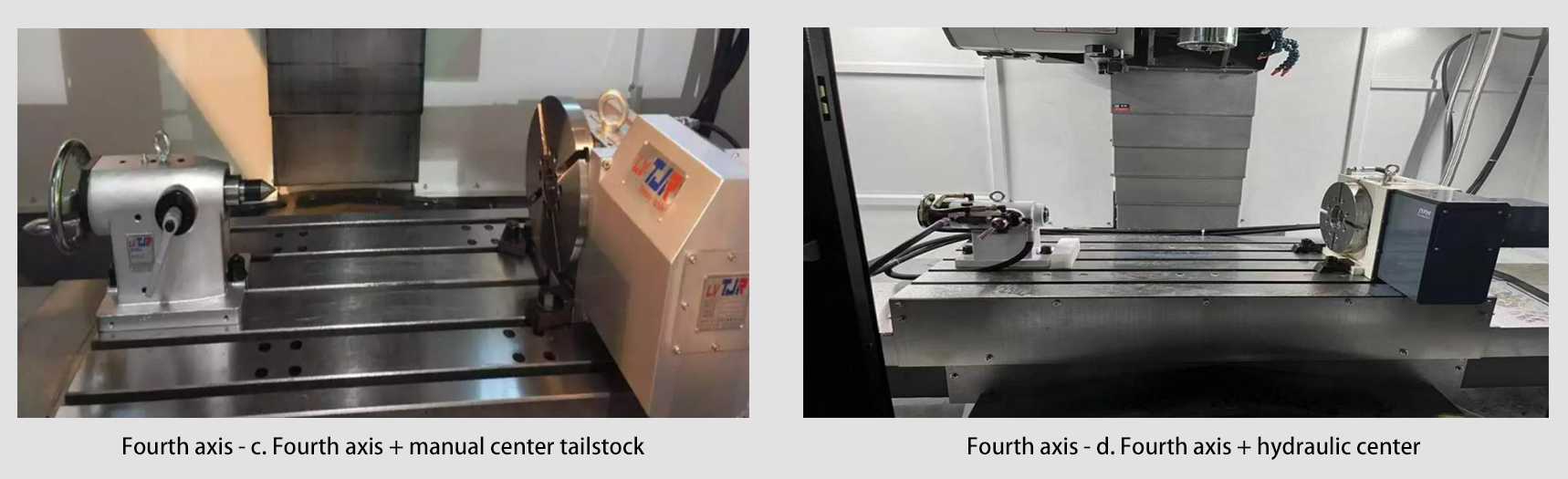

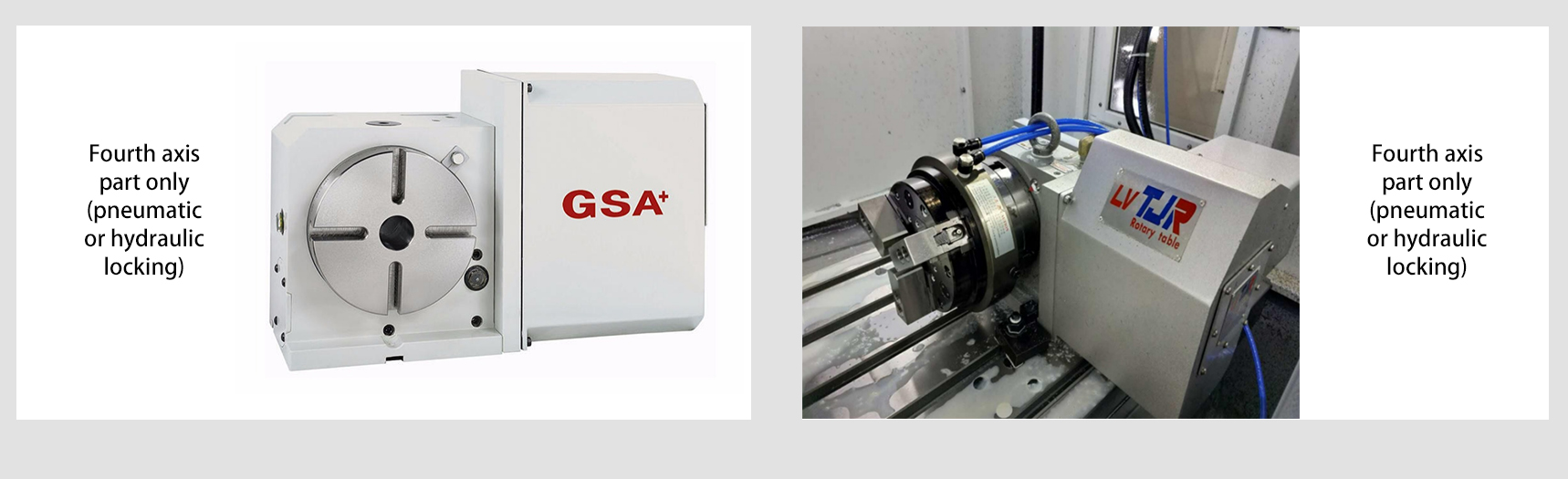

VIII.Rau ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv plaub axis yog muaj raws li cov khoom siv ntxiv:

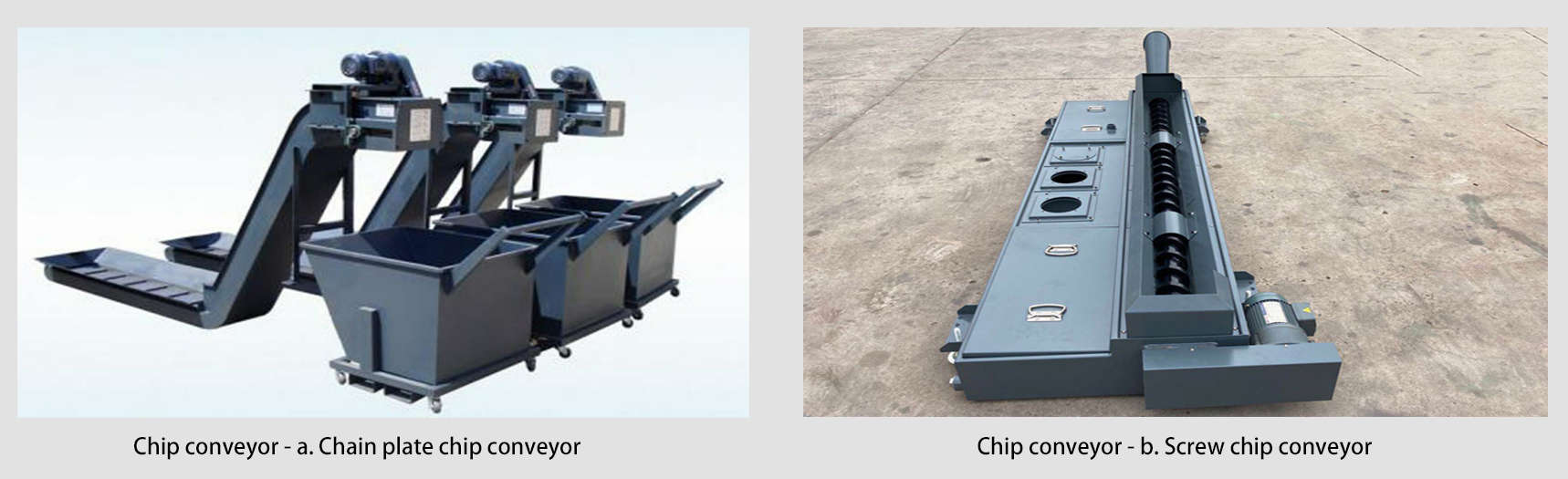

IX. Rau ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv nti conveyor yog muaj raws li cov khoom siv ntxiv:

X. Rau ntau yam ntawm VMC-850 ntsug machining chaw, ib qho kev xaiv thib tsib axis muaj raws li cov khoom siv ntxiv:

| Qauv | VMC-1100A (Peb Txoj Kev Qhia Tawm) | VMC-1100B (Ob kab thiab ib qho nyuaj) | VMC-1100C (Peb Txoj Kev Nyuaj Siab) |

|---|---|---|---|

| Spindle | |||

| Spindle Taper | BT40 | BT40 | BT40 |

| Spindle Ceev (rpm / min) | 8000 (Drect tsav 15,000 rpm, xaiv tau) | 8000 (Drect tsav 15,000 rpm, xaiv tau) | 8000 (Drect tsav 15,000 rpm, xaiv tau) |

| Main Tsav Tsav Fais Fab | 11 kwv | 11 kwv | 11 kwv |

| Fais fab mov muaj peev xwm | 20 | 20 | 20 |

| Kev ua haujlwm ntau | |||

| X-axis Travel | 1100 hli | 1100 hli | 1100 hli |

| Y-axis Travel | 650 hli | 650 hli | 600 hli |

| Z-axis Taug kev | 750 hli | 750 hli | 600 hli |

| Worktable Size | 650 x 1200 mm | 650 x 1200 mm | 600 x 1300 mm |

| Maximum Load ntawm Worktable | 8 00kg | 8 00kg | 8 00kg |

| Workbench T-qhov (quantity – size * spacing) | 5-18 * 90 | 5-18 * 90 | 5-18 * 90 |

| Qhov kev ncua deb ntawm lub spindle axis thiab kem | 6 90mm | 6 60mm | |

| Kev ncua deb ntawm spindle kawg ntsej muag mus rau lub workbench | 110-860 hli | 110-860 hli | |

| Kev ua tsis tau | |||

| Kev nrawm nrawm raws X / Y / Z axes, meters ib feeb | 24/24/24 | 24/24/15 | 15/15/15 hnub |

| Ua hauj lwm pub, millimeters ib feeb | 1-10000 | 1-10000 | 1-10000 |

| Numerical tswj system | |||

| FANUC MF3B | X-axis: βiSc12/3000-B Y-axis: βiSc12/3000-B Z-axis: βis22/3000B-B Spindle: βiI 8/12000-B | X-axis: βiSc12/3000-B Y-axis: βiSc12/3000-B Z-axis: βis22/3000B-B Spindle: βiI 8/12000-B | X-axis: βiSc22/2000-B Y-axis: βiSc12/2000-B Z-axis: βis22/2000-B Spindle: βiI 12/10000-B |

| SIEMENS 828D UAS | X-axis: 1FK2306-4AC01-0MB0 Y-axis: 1FK2306-4AC01-0MB0 Z-axis: 1FK2208-4AC11-0MB0 Spindle: 1PH3105-1DG02-0KA0 | X-axis: 1FK2306-4AC01-0MB0 Y-axis: 1FK2306-4AC01-0MB0 Z-axis: 1FK2208-4AC11-0MB0 Spindle: 1PH3105-1DG02-0KA0 | X-axis: 1FK2308-4AB01-0MB0 Y-axis: 1FK2308-4AB01-0MB0 Z-axis: 1FK2208-4AC11-0MB0 Spindle: 1PH3131-1DF02-0KA0 |

| Mitsubishi M80B | X-axis: HG204S-D48 Y-axis: HG204S-D48 Z-axis: HG303BS-D48 Spindle: SJ-DG7.5/120 | X-axis: HG204S-D48 Y-axis: HG204S-D48 Z-axis: HG303BS-D48 Spindle: SJ-DG7.5/120 | X-axis: HG303S-D48 Y-axis: HG303S-D48 Z-axis: HG303BS-D48 Spindle: SJ-DG11/120 |

| Instrument System | |||

| Tool Magazine hom thiab muaj peev xwm | Disc hom (manipulator hom) 24 daim | Disc hom (manipulator hom) 24 daim | Disc hom (manipulator hom) 24 daim |

| Tool Holder Hom | BT40 | BT40 | BT40 |

| Cov cuab yeej siab tshaj plaws txoj kab uas hla / qhov chaw nyob ib sab | Φ80 / Φ150mm | Φ80 / Φ150mm | Φ80 / Φ150mm |

| Cov cuab yeej siv ntev tshaj plaws | 300 hli | 300 hli | 300 hli |

| Qhov ntsuas qhov hnyav tshaj plaws | 8kg ua | 8kg ua | 8kg ua |

| Qhov tseeb | |||

| Rov ua dua ntawm X / Y / Z Axes | 0.008mm ib | 0.008mm ib | 0.008mm ib |

| Qhov tseeb ntawm X / Y / Z Axes | 0.006mm | 0.006mm | 0.006mm |

| X/Y/Z Axis Guideway Type | Linear phau ntawv qhia X-axis: 35 Y-axis: 45 Z-axis: 45 | Linear guide + Hard guide X-axis: 45 Y-axis: 45 Z-axis: Cov lus qhia nyuaj | Txoj kev nyuaj |

| Ntsia Hlau Specification | 4016/4016/4016 | 4012/4012/4012 | 4010/4010/4010 |

| Yam | |||

| Ntev | 2600 hli | 2600 hli | 2600 hli |

| Dav | 2 880mm | 2500 hli | 2500 hli |

| Qhov siab | 2 750mm | 2 650mm | 2 650mm |

| Qhov hnyav | 7500kg ib | 7 800kg | 7500kg ib |

| Yuav tsum tau Cua Siab | ≥0.6MPa ≥500L / min (ANR) | ≥0.6MPa ≥500L / min (ANR) | ≥0.6MPa ≥500L / min (ANR) |

TAJANE Service Center

TAJANE muaj CNC tshuab cuab tam chaw pabcuam hauv Moscow. Cov kws tshaj lij pabcuam yuav pab koj hauv kev taw qhia kev teeb tsa, kev debugging, kev kuaj xyuas cov cuab yeej, kev saib xyuas, thiab kev cob qhia kev ua haujlwm ntawm CNC tshuab cuab yeej.Lub chaw pabcuam muaj lub sijhawm ntev ntawm cov khoom seem thiab cov khoom siv rau tag nrho cov khoom.