Vertical Machining Center VMC-1890

Cov ntaub ntawv nthuav dav: Lub TAJANE ntsug machining center series yog cov cuab yeej siv lub tshuab muaj zog, feem ntau yog tsim rau kev ua haujlwm nyuaj xws li daim hlau, daim hlau, pwm, thiab cov plhaub me me. Qhov no series ntawm machining chaw txais yuav ib tug ntsug qauv tsim thiab muaj cov yam ntxwv ntawm high precision, high efficiency, thiab siab stability.

Thaum lub sij hawm machining txheej txheem, TAJANE ntsug machining chaw series paub txog automation thiab kev txawj ntse ntawm cov txheej txheem machining los ntawm kev tswj cov tshuab thiab automation technology. Cov neeg ua haujlwm tsuas yog xav tau cov ntsiab lus tseem ceeb los ntawm kev ua haujlwm yooj yim kom paub txog kev tswj hwm ntawm cov txheej txheem ua haujlwm, txhim kho kev tsim khoom thiab ua kom raug.

Tsis tas li ntawd, TAJANE ntsug machining center series kuj muaj qhov zoo scalability thiab yoog raws, thiab tuaj yeem hloov kho thiab teeb tsa raws li kev ua haujlwm sib txawv kom tau raws li qhov xav tau ntawm cov neeg siv sib txawv. Qhov no series ntawm machining chaw yuav ua tiav milling, tho txawv, drilling, tapping, xov txiav thiab lwm yam txheej txheem, thiab yog dav siv nyob rau hauv aerospace, tsheb tsim, pwm ua, machinery manufacturing thiab lwm yam teb.

Nyob rau hauv luv luv, lub TAJANE ntsug machining center series yog ib tug zoo heev ua khoom siv nrog cov yam ntxwv ntawm high precision, high efficiency, siab stability, thiab lwm yam., thiab yog dav siv nyob rau hauv kev ua ntawm ntau yam complex qhov chaw. Txawm nyob rau hauv lub teb ntawm aerospace, tsheb tsim, pwm ua los yog machinery manufacturing, lub TAJANE ntsug machining center series yuav muab cov neeg siv nrog zoo heev machining daws.

Khoom siv

Lub chaw ntsug machining yog lub tshuab siv lub tshuab muaj zog uas siv dav hauv kev ua cov khoom siv 5G, cov khoom siv tsheb, lub thawv qhov chaw thiab ntau yam pwm. Nws muaj cov yam ntxwv ntawm kev ua haujlwm siab, kev ua haujlwm siab thiab ruaj khov, thiab tuaj yeem ua tau raws li cov kev xav tau ntawm ntau qhov chaw. Vertical machining centres ua tau zoo hauv kev ua cov khoom precision rau 5G cov khoom, batch ua ntawm lub plhaub qhov chaw, batch ua ntawm lub tsheb qhov chaw, high-ceev ua ntawm lub thawv qhov chaw, thiab ua ntau yam pwm qhov chaw. Lawv tuaj yeem muab koj nrog Muab cov kev daws teeb meem zoo heev.

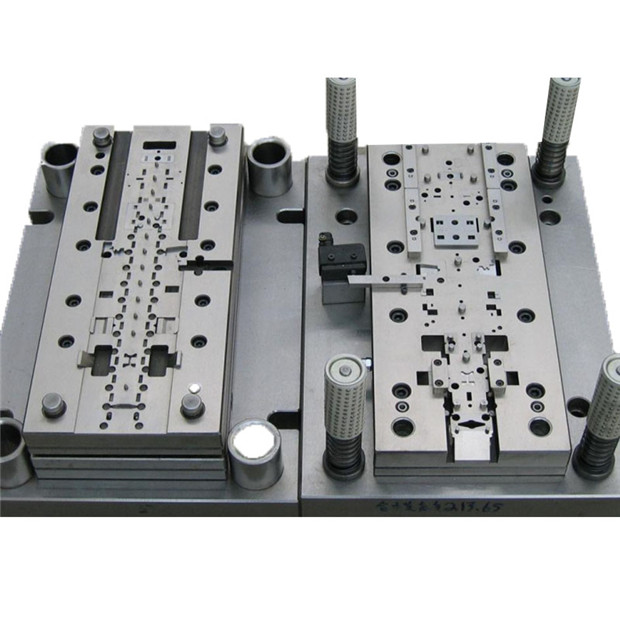

Vertical machining chaw, siv rau machining precision qhov chaw ntawm 5G khoom.

Lub ntsug machining chaw ua tau raws li batch ua ntawm plhaub qhov chaw.

nws ntsug machining chaw tuaj yeem paub batch ua ntawm nws pib qhov chaw.

Vertical machining center tuaj yeem paub qhov kev ua haujlwm siab ceev ntawm lub thawv qhov chaw.

Vertical machining center ua tau raws li kev ua haujlwm ntawm ntau yam pwm

Cov txheej txheem casting khoom

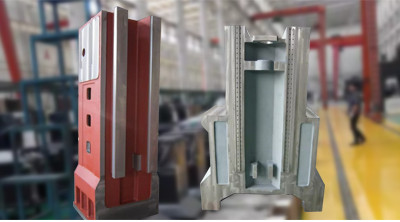

CNC ntsug machining chaw txais yuav Meehanite casting txheej txheem los txhim kho cov hnav tsis kam thiab stability ntawm castings. Lub ob-phab ntsa daim phiaj-zoo li rib qauv nyob rau hauv lub casting ntxiv txhim khu lub rigidity thiab lub zog ntawm lub tshuab cuab yeej. Lub thawv spindle muaj qhov kev tsim kho kom zoo thiab tsim qauv tsim nyog, muab kev ua haujlwm siab dua thiab ua haujlwm tau zoo. Lub ntuj tsis ua hauj lwm ntawm lub txaj thiab kem zoo txhim kho qhov tseeb thiab ruaj khov ntawm lub tshuab machining chaw. Tus tsim ntawm lub worktable tus ntoo khaub lig swb thiab lub hauv paus ua tau raws li qhov xav tau ntawm kev txiav hnyav thiab txav ceev, muab cov neeg siv nrog kev ua haujlwm zoo dua thiab ruaj khov. CNC ntsug machining chaw yog cov cuab yeej ua haujlwm nrog kev ua haujlwm zoo thiab muaj zog ua haujlwm, uas yog siv dav hauv ntau yam kev ua haujlwm.

CNC VMC-1890 yog tsim los ntawm cov khoom siv hluav taws xob.

CNC ntsug machining chaw, sab hauv ntawm lub casting txais ob-walled daim phiaj-zoo li tus tav qauv.

CNC ntsug machining chaw, lub thawv spindle txais kev tsim qauv tsim nyog thiab tsim nyog.

Rau CNC machining chaw, lub txaj thiab txhua kab tsis ua haujlwm, txhim kho qhov tseeb ntawm qhov chaw machining.

CNC ntsug machining chaw, rooj hla swb thiab hauv paus, kom tau raws li kev txiav hnyav thiab txav ceev

Boutique Parts

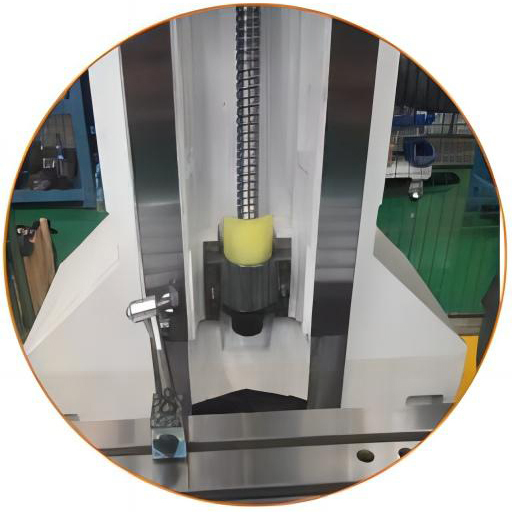

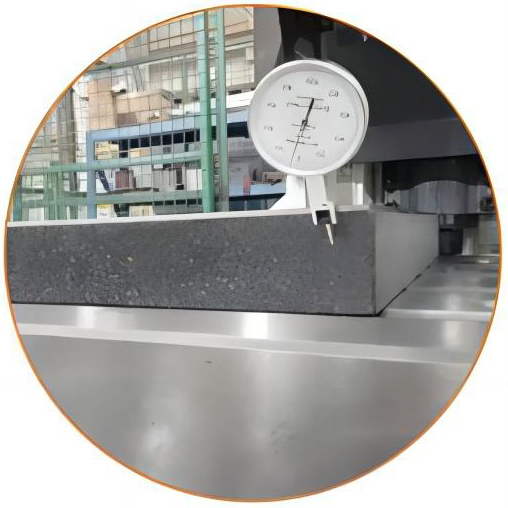

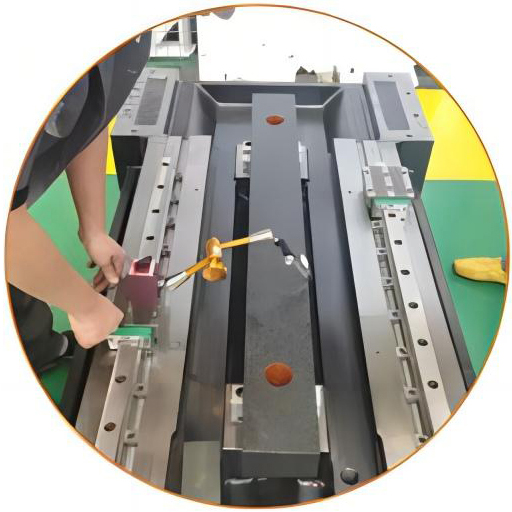

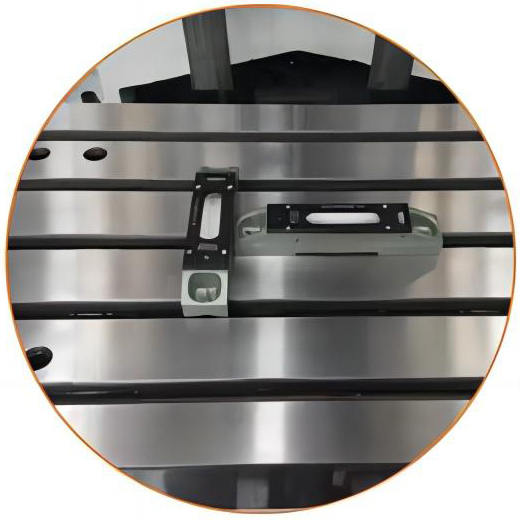

Precision sib dhos soj ntsuam txheej txheem

Workbench Qhov Ntsuas Qhov Ntsuas

Opto-Mechanical Component Inspection

Verticality Detection

Kev Tshawb Nrhiav Parallelism

Txiv Ntseej Rooj Qhov Ntsuas Qhov Ntsuas

Angle Deviation Detection

Configure hom CNC system

TAJANE ntsug machining chaw tshuab cov cuab yeej, raws li cov neeg siv khoom xav tau, muab ntau hom CNC tshuab kom tau raws li cov neeg siv khoom xav tau sib txawv rau ntsug machining chaw, FANUC, SIEMENS, MITSUBISH, SYNTEC, LNC.

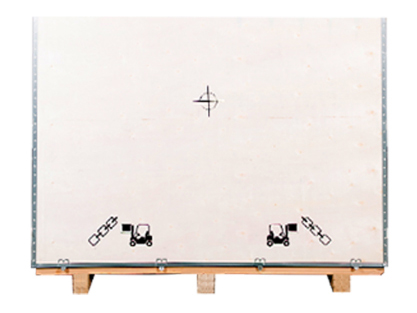

Tag nrho cov ntim ntim, escort rau kev thauj mus los

Cov khoom ntim ntoo puv nkaus

CNC VMC-1890 ntsug machining chaw, tag nrho ntim pob, escort rau tsheb thauj mus los

Nqus ntim rau hauv lub thawv

CNC ntsug machining chaw, nrog noo noo-pov thawj lub tshuab nqus tsev ntim hauv lub thawv, haum rau kev thauj mus los ntev-ntev

Ntshiab cim

CNC ntsug machining chaw, nrog cov cim meej hauv lub thawv ntim khoom, thauj khoom thiab tshem tawm cov cim, qauv hnyav thiab qhov loj me, thiab kev lees paub siab

Khoom ntoo hauv qab bracket

CNC ntsug machining chaw, hauv qab ntawm lub thawv ntim khoom yog ua los ntawm cov khoom ntoo, uas yog ib qho nyuaj thiab tsis plam, thiab fastens rau xauv cov khoom.

| Qauv | Chav tsev | VWM-1890 | |

| TRAVEL | X x Y x Z axis | hli (inch) | 1800 x 900 x 600 (70.9 x 35.5 x 23.60) |

| Spindle qhov ntswg rau lub rooj | hli (inch) | 160 ~ 760 (6.3 ~ 30.0 hli) | |

| Spindle nruab nrab rau cov kab nrib pleb | hli (inch) | 950 (37.40 hli) | |

| TABSIS | Chaw ua haujlwm | hli (inch) | 2000 x 900 (78.74 x 35.43) |

| Max. thauj khoom | kg | 1600 | |

| T-Slots (No. x Dav x Pitch) | hli (inch) | 5 x 22 x 165 (4 x 0.7 x 6.5) | |

| PINDLE | Tool shank | - | BBT-50 |

| Ceev | rpm ua | 6000 | |

| Kev sib kis | - | Belt Tsav | |

| Cov kabmob lubrication | - | Roj | |

| Txias qhov system | - | Roj txias | |

| Spindle zog (nruam / overload) | kw (HP) | 22 (28.5) thiab | |

| NYIAJ PAB | Ceev ceev ntawm X&Y&Z axis | m/min | 20/20/15 |

| Max. txiav feedrate | m/min | 10 | |

| TUAJ MAGAZINE | Cov cuab yeej cia muaj peev xwm | pcs | 24 arm ib |

| Hom cuab yeej (yeem) | hom | BT50 | |

| Max. cuab tam diam | hli (inch) | 125 (4.92) ib | |

| Max. twj luj | kg | 15 | |

| Max. cuab tam ntev | hli (inch) | 400 (15.75) Nws | |

| AVG.Hloov sij hawm (ARM) | Tool rau tool | sec. | 3.5 |

| Cua qhov chaw yuav tsum tau | kg/cm² | 6.5up ua | |

| YOG | Qhov chaw | hli (inch) | ± 0.005/300 (± 0.0002/11.81) |

| Rov ua dua | hli (inch) | 0.006 tag nrho ntev (0.000236) | |

| DIMENSION | Tshuab hnyav (Net) | kg | 13 000 |

| Lub zog yuav tsum tau | KVA | 45 | |

| Qhov chaw hauv pem teb (LxWxH) | hli (inch) | 4950 x 3400 x 3300 (195 x 133 x 130) |

Standard Accessories

● Mitsubishi M80 maub los

●Spindle ceev 8,000 / 10,000 rpm (nyob ntawm lub tshuab qauv)

● Tsis siv neeg lub cuab yeej hloov pauv

●Txoj kev tiv thaiv tag nrho

● Kub exchanger rau hluav taws xob txee

● Tsis siv neeg lubricating system

● Spindle roj txias

● Spindle cua blast system (M code)

● Spindle orientation

● Txias rab phom thiab lub qhov (socket) cua

● Cov khoom siv theem

● Tshem tau phau ntawv & mem tes generator (MPG)

● LED teeb

● Rigid tapping

●Coolant system thiab tank

● Cycle finish indicator thiab tswb

●Tool Box

● Kev khiav hauj lwm thiab tu phau ntawv

● Transformer

● Spindle coolant nplhaib (M code)

Xaiv cov khoom siv

●Spindle ceev 10,000 rpm (Direct type)

●Coolant los ntawm spindle (CTS)

● Tsis siv neeg lub cuab yeej ntsuas qhov ntev

● Tsis siv neeg ua haujlwm ntsuas qhov system

● CNC rotary rooj thiab tailstock

● Roj skimmer

● Txuas hom nti conveyor nrog nti thoob

● Linear nplai (X / Y / Z axis)

●Coolant los ntawm cov cuab yeej tuav